Solutions

Power Consumption & Industries

Light Industrial Machinery

Large Experimental Platforms

Rail Transit

Mining Machinery

Petrochemical Industry

Ferrous Metallurgy

Power Consumption & Industries

Light Industrial Machinery

Large Experimental Platforms

Rail Transit

Mining Machinery

Petrochemical Industry

Ferrous Metallurgy

Products

all products

Solar Inverter

PV Grid-Tied Inverter

PV Turnkey Solution

Energy Storage System

Power Conversion System (PCS)

PCS Turnkey station

Windpower Devices

Doubly-fed Converter

Full Power Converter

Pitch Control System

Hydrogen Energy

DC/DC Converter

AC/DC Single-Stage Topology

AC/DC+DC/DC Two-Stage Topology

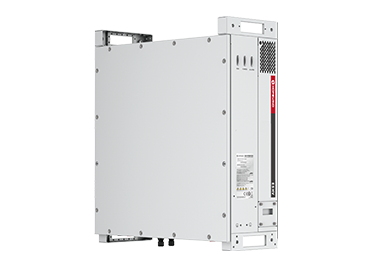

VFD

Medium voltage VFD

Low-voltage Engineering VFD

Low-voltage VFD

Other Station-level Devices

AC Source

STATCOM

10KV direct hanging

35KV direct hanging

Remote Intelligent O&M System

hopeEMS Energy Management System

Français

Français